Model E: 18 *42' (5m x 12m)

Material: 3mm Solid Polycarbonate Sheet, Aluminum Profile

Outer size: 20.29′ * 42.87 ‘ * 5.81’

Inner Size: 18.3′ * 42.32′ * 4.93′

Wooden Box Size: 3460*1500*760mm

Excelite Swimming Pool Enclosure

- 15 year warranty

- Allows swimming in all seasons

- Reduces maintenance costs

1. Light transmission

Light transmission: Solid polycarbonate sheets transmit up to 85%-91% of light, and the transparency can be comparable with glass.

2. High Impact Resistance

High impact resistance: Polycarbonate is 250-300 times stronger than normal glass, and 2 times stronger than toughened glass. It even enjoys the reputation of “safety glass” and “ring steel”.

3. Anti- UV protection

Anti- UV protection: There are anti-UV coatings on the surface of the solid polycarbonate sheets which protect your skin from damaging rays.

6063 T5 Aluminium Frame

Extruded 6063 aluminium has high wind pressure and corrosion resistance. The anodized aluminium has a lesser rate of oxidation on the surface so the aluminium has superior corrosion resistance in seawater. The corrosion rate is less than 0.018mm/Y in seawater. This translates to better protection from all the elements.

Model B Pool Enclosure

Tracks

Not sharp on top. Comfortable to walk over. Will not hurt your feet.

Door

Stand door covers have a front door with brush under door panel.

Lock system

Underground lock on front door and locks between sections, so you do not have to worry about wind blowing it away.

15-year warranty

We provide a 10-year warranty on the panel and equipment accessories, and a 15-year warranty on the aluminium.

1. Design

2. Material:

Panel material: 3 mm thick solid polycarbonate sheets

Light transmittance: Solid polycarbonate sheets transmit up to 85%-91% of light. The transparency level can be comparable with glass.

High impact resistance: Polycarbonate is 250-300 times stronger than normal glass, and 2 times stronger than toughened glass. You can throw a 3 kg hammer from two meters above the polycarbonate and there will absolutely be no crack. Can you imagine how strong the material is? It even enjoys the reputation of “safety glass” and “ring steel”. These capabilities greatly reduce maintenance costs and risk liability compared to other glazing materials.

Anti- UV protection: We add anti-UV coatings on the surface of the sheets so they can protect you from skin cancer. It is also anti-aging.

Frame material: 34mm*50mm 6063 T5 aluminium alloy

Extruded 6063 aluminium resists corrosion, high wind pressures and is widely used as the frame for windows, doors and curtain walls.

The aluminium was anodized, has oxidation on the surface. The coating serves as a shield, preventing corrosive substances such as salt water, salt mist, and corrosive glass from affecting the metal. In addition, the aluminium has high corrosion resistance to seawater, with a corrosion rate of less than 0.018mm/Y.

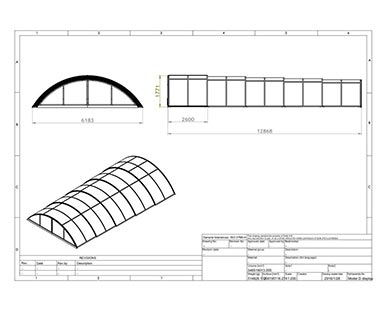

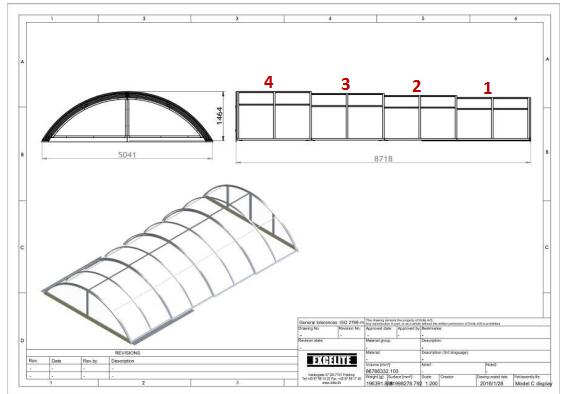

3.Sizes

Model C is divided into 4 sections, as shown in the picture above.

Inner size 4576*8650*1250mm (15.01’*28.38’*4.1’);

Outer size 5041*8718*1464 mm (16.54’*28.60’*4.80’)

4.Tracks

Tracks are fixed on flat hard ground. Width of tracks: (outer width 5041 mm– inner width 4576 mm)/2=232.5mm. You can also extend the tracks by 2m (for an additional cost of 80USD).

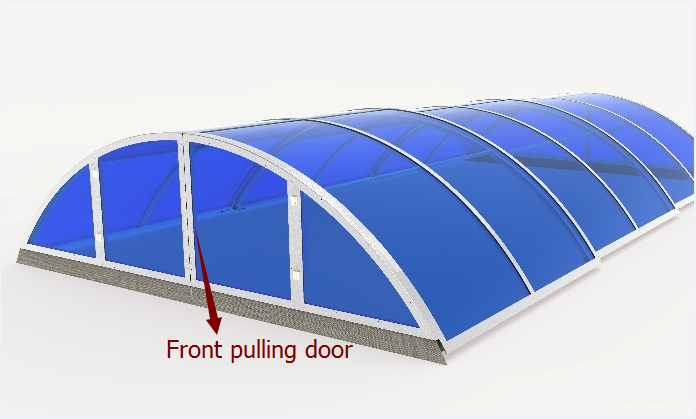

5.Door

Usually our standard pool cover has a front pulling door as showed in the picture below, if you want to add a side sliding door, we can customize one for you.

The front door is shown below. We can customize the side door for an additional 150 USD.

Usually the front door will be located in the biggest section; you can also add a front door in the smallest section for an additional cost of 350 USD. The radian of the door panel will change, and the current door system in the biggest section will not work. Our engineer would need to re-design it.

Example of the side sliding door below

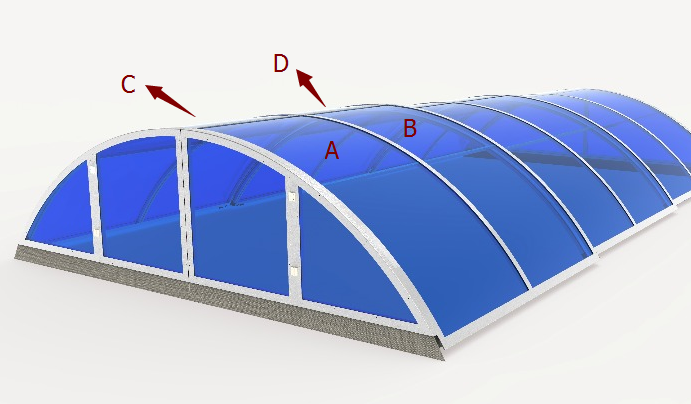

The side sliding door can be located at the A,B,C or D panel as shown below.

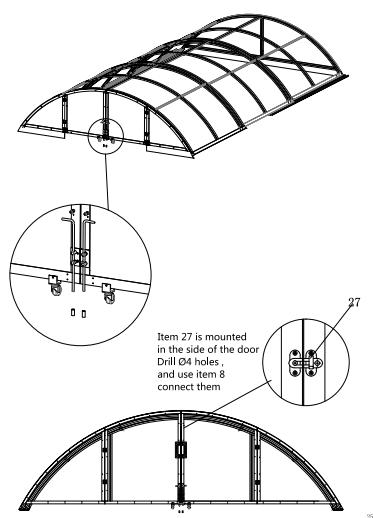

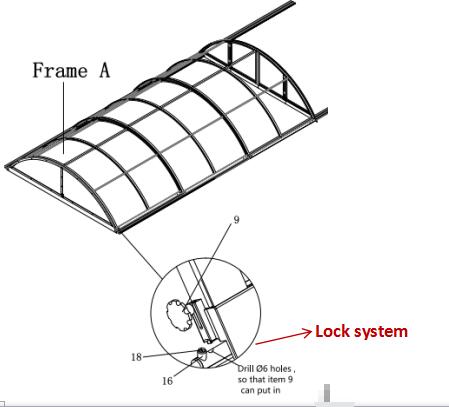

6. Locking systems

On one hand, there is a lock on the front door; on the other hand, there is a lock system between sections. So when you open the whole unit, it will remain fixed very well, you do not have to worry about the wind blowing it away.

Front door system

Each sections lock system

8. Installation

We provide manuals with step-by-step instructions on how to complete the installation. If necessary, our engineer can also give you video or telephone guidance. If you require further assistance, our experts can also fly to your country, but you may need to bear the necessary cost.

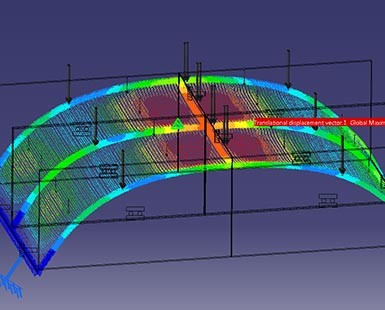

9. Wind and snow pressure tests

We construct our enclosures from solid polycarbonate sheets and extruded aluminium, they can withstand winds of up to 230km/hr (142mph) and a weight equivalent to 900 kg (1984 lb) distributed within a 1.5m radius. You don’t need to worry about wind or snow anymore, and you will have a safe pool cover all year round.